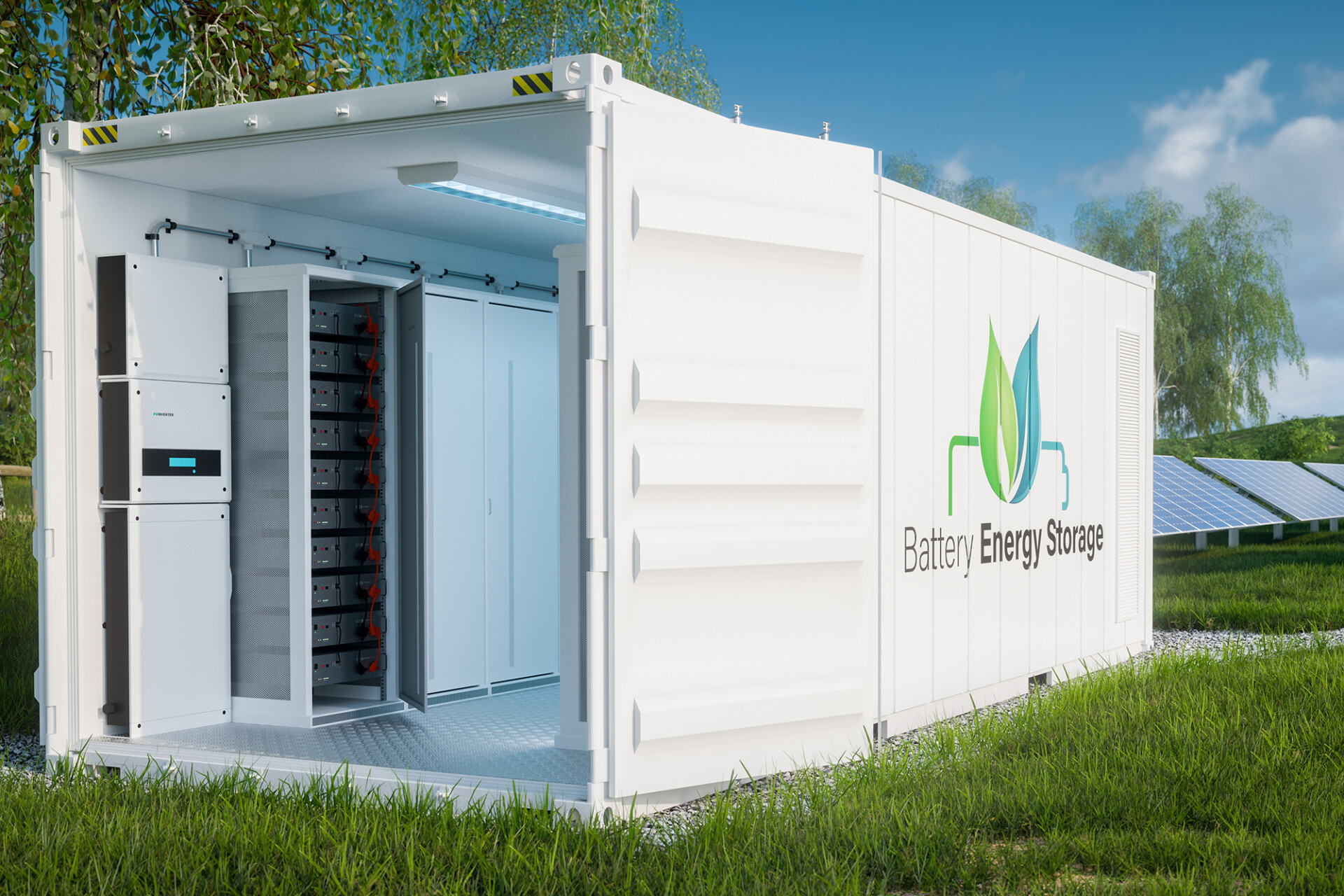

Battery Energy Storage Systems

Scalable and reliable management for BESS applications

Dukosi Cell Monitoring System (DKCMS™) helps deliver the performance, reliability and safety gains needed for next generation, large-scale battery storage systems. The flexible architecture delivers benefits for grid, load shifting, peak shaving, behind the meter and other energy storage applications.

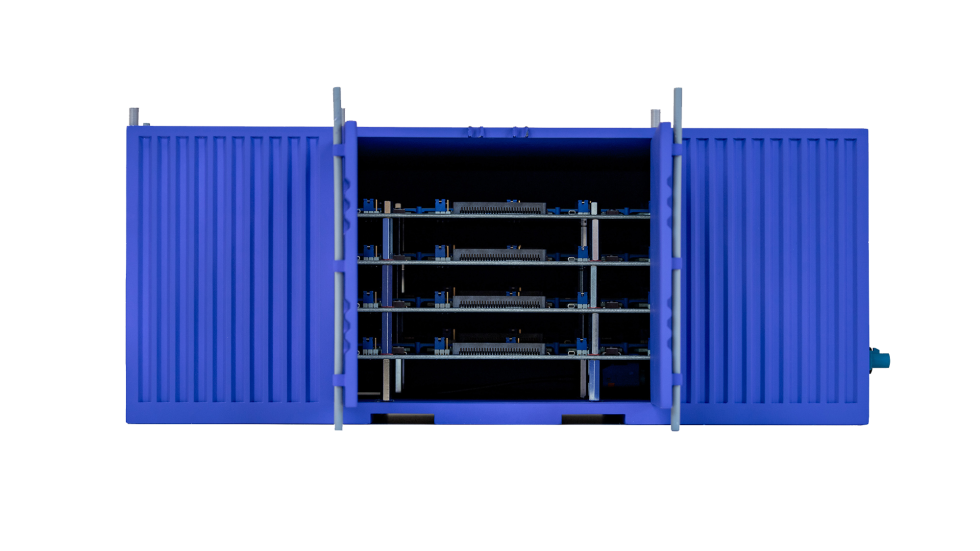

Highly scalable architecture

Capable of supporting over 200 cells from a single Dukosi System Hub, and able to scale with multiple System Hubs per BMS, the DKCMS can accommodate the largest energy storage systems.

The flexible design allows more cells to be dropped in or replaced when required, even without shutting down the BMS. The patented, contactless communication architecture using near-field technology means the changes are picked up immediately, without having to fuss with a complex wiring harness.

This scalable solution enables new architectures like cell-to-pack, providing manufacturing flexibility to accommodate new designs.

Reliable charging

Cell-level measurements for temperature and voltage provide extremely accurate and synchronized data for the BMS, which in turn can ensure all the cells in a pack work closer to their optimum operating temperature, avoiding overheating, overvoltage, or erroneous events, allowing the battery pack to charge faster with confidence.

54 Channel BESS Module Reference Design Available

Accelerate new battery designs using the Dukosi 54 Channel Reference Design that easily integrates with leading BMS host processors to create BESS modules suitable for a typical 900-1500V battery rack. The reference design demonstrates the numerous advantages that DKCMS with C-SynQ® offers product designers.

Greater system safety and reliability

DKCMS allows every cell in the battery pack to be monitored 24/7, even when the main BMS controller is in a low-power state. This provides immediate detection of cell-level problems, and earlier fault diagnosis, creating a safer, more reliable energy storage systems.

24/7 measuring of every cell’s temperature enables safer batteries, as any cell experiencing an elevated temperature can be identified immediately. This detection is at least 5 minutes earlier than battery packs without cell-level temperature measurement, which can be crucial to give more time for people or safety systems to act in response to such events.

Enabling a circular economy and sustainable battery chain

By capturing and storing lifetime data on each cell, DKCMS promotes a circular economy (reduce, reuse, recycle) throughout the battery value chain. When the Dukosi Cell Monitor is implemented at an early stage in cell manufacturing, the solution offers lifetime traceability and helps operators to show compliance with the latest regulations.

More usable energy per cell

DKCMS provides extremely accurate and synchronized data insights with essential synchronization, allowing more usable energy extracted per cell, maximizing the potential capacity of each battery. With each Dukosi Cell Monitor providing highly accurate granular information into each cell’s behavior and lifetime status, it provides better insights into a battery pack’s long-term use, giving the confidence to unlock more energy from each cell while still achieving the same reliability standards.

Reduce costs, optimize and automate manufacturing

DKCMS requires fewer components per battery pack, which in turn simplifies the manufacturing process and supply chain, reducing materials costs, and it can potentially enable a fully automated assembly line by eliminating time-consuming manual assembly line steps when installing wires, connectors, and pins.

Working with Dukosi

At Dukosi, we are driven by our mission to bring revolutionary changes to battery-powered applications. To achieve this, we put active collaboration into practice at technical, operational and strategic levels with our customers and partners. Our partners have been selected based on shared commitment to innovation and excellence, and their ability to deliver strong and trustworthy solutions that help accelerate customers’ development efforts and expedite time to market.